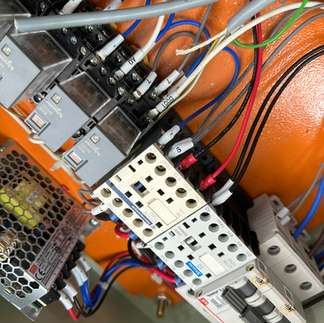

Checkweigher Control Panel

- aerotempeng

- Oct 18, 2024

- 1 min read

A Checkweigher Control Panel is an essential component of any industrial weighing and packaging process, designed to ensure accurate weight measurement of products in motion.

Features:

Real-time Weight Monitoring: Provides precise, real-time weight data for products on conveyor systems.

Automated Sorting: Automatically rejects products that do not meet weight specifications, ensuring quality control.

User-Friendly Interface: Equipped with an intuitive touchscreen or digital display for easy operation and data management.

Customizable Settings: Offers flexible calibration options to suit different production lines and product types.

Data Logging: Stores weight data for audit purposes and production optimization.

Durability: Built with robust materials to withstand industrial environments.

Applications:

Food & Beverage Industry: Ensures compliance with regulatory weight standards by accurately checking product weights before packaging.

Pharmaceuticals: Guarantees precise dosages by monitoring and rejecting non-compliant items.

Manufacturing: Used in production lines to maintain consistency in product weight and avoid costly recalls due to underweight or overweight products.

Logistics: Helps verify the weight of packages for shipping and delivery accuracy.

The Checkweigher Control Panel enhances efficiency, reduces waste, and improves overall product quality across various industries.

Comments